Quality assurance is our commitment

What we have?

01

Thread Plug Gauge & Ring Gauge

02

Pin Gauge

03

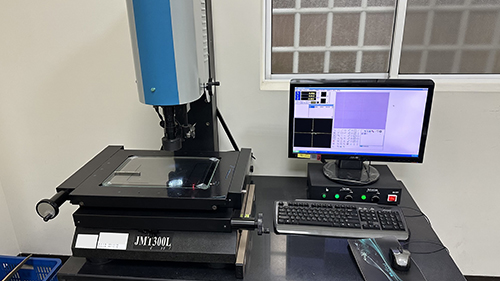

2.5D Image Measuring Instrument

04

Height Gauge

05

Coordinate-measuring machine

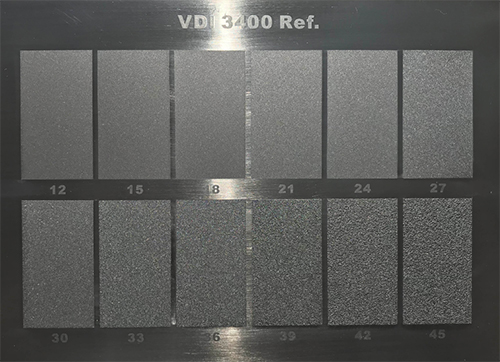

Surface pattern

(Picture from VDI3400)

- The surface patterns of plastic products can provide various visual and tactile sensation based on the pattern's roughness.

We use VDI 3400 as reference standard for surface roughness.。

Color & lustre

- For painting products, you can specify commonly used RAL or PANTONE color numbers (for the Japanese market, you can refer to NIPPON COLORS) or provide samples for comparison.

Our Goal

Strictly quality control is the key to our success at JiingDuen.

We strive to ensure that every customer is satisfied with the products they receive, allowing them to collaborate with us confidently. We also welcome customer feedback, as it helps us gain experience in solving different problems.

Quality Inspection Process

We follow strict SOP to ensure that the final product can meet customer requirements.SOP introduction:

-

Step1

IQC(Incoming Quality Control):Beginning from raw materials, only standard raw materials can go through the production process.

IQC(Incoming Quality Control):Beginning from raw materials, only standard raw materials can go through the production process.

-

Step2

PQC(Process Quality Control):During the production process, inspect the first sample and perform quantitative sampling to ensure compliance with standards throughout the process.

PQC(Process Quality Control):During the production process, inspect the first sample and perform quantitative sampling to ensure compliance with standards throughout the process.

-

Step3

FQC(Final Quality Control):After the products are completed, they will undergo inspection to ensure that each part meets the standards.

FQC(Final Quality Control):After the products are completed, they will undergo inspection to ensure that each part meets the standards.

-

Step4

OQC(Outgoing Quality Control):Before the products are shipped, we will conduct random sampling inspections to ensure quality. Additionally, we will inspect the packaging to ensure that customers can receive intact products.

OQC(Outgoing Quality Control):Before the products are shipped, we will conduct random sampling inspections to ensure quality. Additionally, we will inspect the packaging to ensure that customers can receive intact products.